For reliable and efficient molten salt transfer, trust the WEMPump.

For the Transfer of Molten Salts

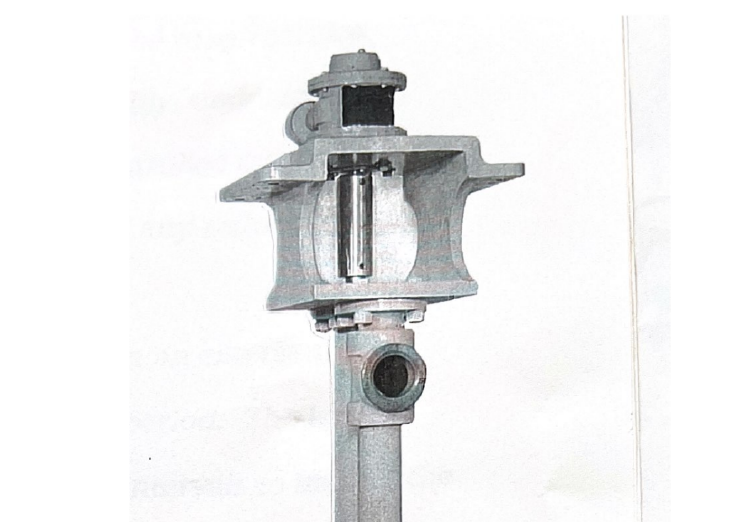

The smaller version of our salt transfer pump is built using a similar design to our original 3HP pump, but optimized for use in tighter, space restricted environments.

During emergencies or maintenance operations, a single operator can safely handle the pump, effectively managing pan failure during shutdown periods. With the ability to economically lower the zinc level at intervals, inspections of the pan can be conducted to detect failures before they occur, protecting brickwork and burners from damage caused by leaking zinc.

The pump can be conveniently hung from a crane or chain hoist, allowing for continuous filling of containers or molds by pivoting the discharge pipe. Ordinary 50-gallon oil drums make excellent containers, and no cleaning is required after use as the pump is self-draining.

The pump can be used in a variety of industrial applications where molten salt is used, including:

The pump can also be used to transfer a variety of molten salts, including:

Type | Submerged intake, vertical shaft, centrifugal with variable speed and variable discharge |

Power | 1 HP vane-type air motor, cooled and lubricated through the airline, direct coupled to the impeller shaft |

Max Operating Temperature | 1700F |

Materials | Stainless Steel Construction – submerged components made of chrome-nickel alloy |

Available Sizes | 3, 4 and 5 foot pump lengths |

Capacity | 200 – 900 lb/min |